|

Hejianshi Tengda Petroleum Supplies Co.,Ltd

|

TCI tricone bit 14 3/4 tricone drill bits tricone drill bi

| Price: | 200.0~20000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1) ISO9001&API

2)Covers all IADC codes

3)Size:3 1/2"~26"

4)Used for oil well and water well

Specifications

1.Tungsten carbide insert tooth, sealed and gage protection journal bearing

2.Meet strictly of API and ISO standard

2.Meet strictly of API and ISO standard

Production Description:

These tungsten carbide insert bits are used to drill soft formation with low compressive strength and high drill ability, such as shale, clay, sandstone and soft limestone, etc.

1. Tungsten carbide insert tooth, sealed and gage protection journal bearing,hardfaced head bearing surface. cone bearing inlaid with friction reducing alloy and then silver plated. the load capacity and seizure resistance of the bearing is greatly improved

2.O- ring seal is made of the more wear resistance high saturated buna-N with the section and precissely designed sealing flange in the cone sealing area increased the reliability of the seal.

3.The bit bearing is ball which can be applied to high rotary speed drilling.

4.All rubber compensator is used which can provides the bearing system with good assurance of lubrication

3.The bit bearing is ball which can be applied to high rotary speed drilling.

4.All rubber compensator is used which can provides the bearing system with good assurance of lubrication

5.New type of grease that can sustain high temperature up to 250C is utilized.

6.High wear resistance and excellent cutting ability of the insert bit are given full play by using carbide compacts of high strength and high touhness in combination with optimized comjpact numbers and rows, the exposure height and special shaped compacts.

7.Meet strictly of API standard

7.Meet strictly of API standard

8.Manufacturer of TCI tricone bits, steel tooth tricone bits and PDC bits

9.High quality, reasonable price and best service.

10.Delivery on time

11.Good feedback of the clients

12.Be used for water well, oil field, underground, construction, geothermal well,etc

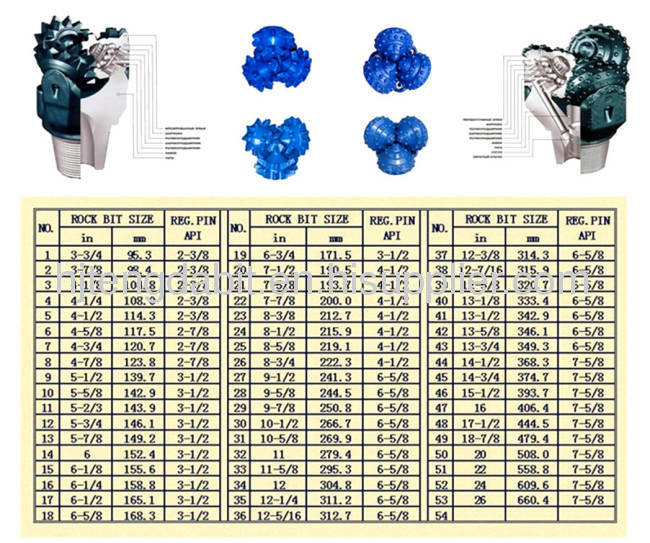

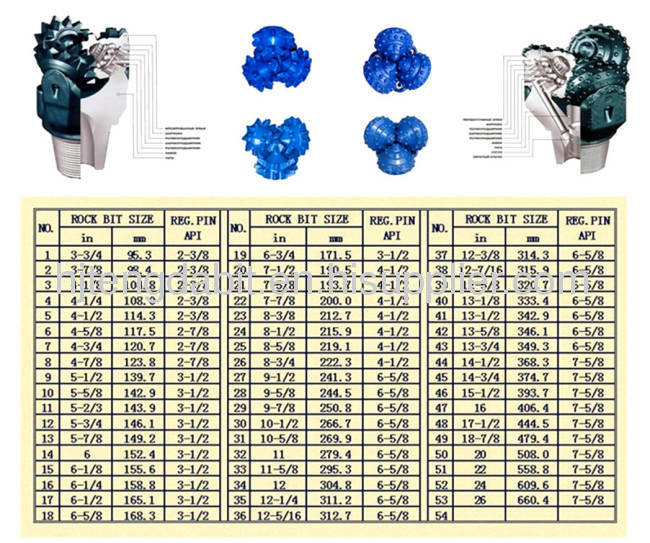

Size Available:

From 3 7/8"(98.4mm) to 26"(660.4mm)

Note:

Sizes and types that are not shown above can be customized according to specific drilling requirements

Product details:

operation process:

Product details:

operation process:

Certification:

If you are intrested in our products,feel free to contact me:

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Tci Tricone Rock Bit

Tricone Rock Bits

Milled Tooth Tricone Bits

Rock Tricone Bit

Drill Bit

Tile Drill Bits

More>>